Use Case 1 – Vehicle components delivery between two production sites

Our Turkish pilot gives the first steps in upgrading the truck fleet in Istanbul from a diesel-based powertrain to an electric powertrain.

Ford Otosan is piloting a 16-ton electric truck to deliver essential automotive parts between their production sites in Turkey. This 6-month project aims to assess the truck’s viability in real-world scenarios. The 230 km route will expose the truck to diverse weather conditions, traffic patterns, and some urban driving. Notably, the truck boasts a lightweight chassis to maximize payload capacity and utilizes eco-driving algorithms to optimize routes and speed for maximum efficiency. This pilot project represents a strategic entry point for Ford Otosan to explore electric truck technology, potentially paving the way for future advancements in the 16T electric distribution truck sector.

This pilot will address:

- Zero emissions in the urban and intercity area with the same service and performance as the current vehicles equipped with internal combustion engines

- Equal or improved functionality than conventional vehicles regarding acceleration, braking, automatic control and electronic regulation

- Intelligent thermal management reducing load and energy usage for climate control and battery cooling

- Reduction of noise and emissions in cities

- DC charging

- Tailored eco-routing strategies.

- Improved efficiency at the fleet level, with cloud-based, closed-loop vehicle communication that enables real-time mission, vehicle load and charge planning.

Objectives

| 10% improvement in overall efficiency |

| Demonstrate at least 200 km average daily operation in real conditions (between Eskisehir and Golcuk plants: 198 km) over at least 6 months |

| Synergies with shorter range/lower payloads urban and suburban applications in the municipal waste collection or construction activities |

| Development of lightweight chassis and integration of electric powertrain components |

Innovations

- Improved thermal management model

- Digital twins

- Electric powertrain-based lightweight and modular platform that leads to payload increase compared to current ICE trucks and reduction of TCO.

- DC overnight charging infrastructure and strategy.

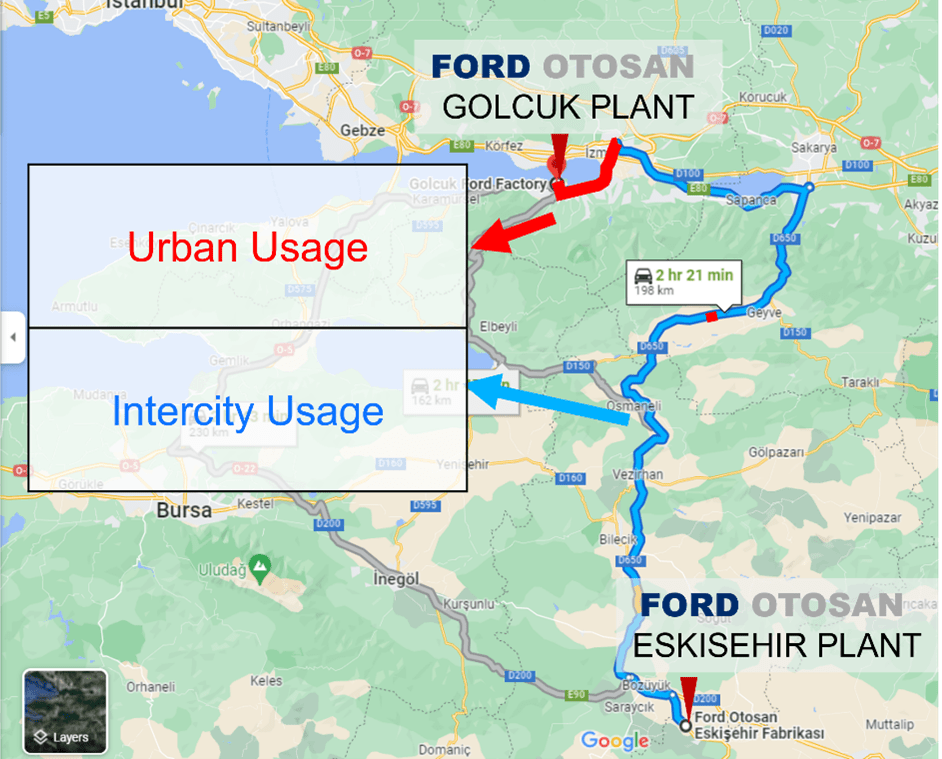

The Route

Route #1

Between FORD Otosan Golcuk and Eskisehir plants. This route includes 10% urban roads and 90% intercity roads. The route length is 198 km.

Route #2

Between FORD Otosan Golcuk and Eskisehir plants. This route includes 15% urban roads and 85% intercity road. The route length is 230 km.

Route #3

This route involves travelling from the Ford Otosan Gölcük Factory to the Kartepe Ski Resort and back. This route will be used 20% of the time during the entire demo. The purpose of this route is to collect data on vehicle performance in extreme cold weather conditions and high altitudes. The route itself is 82 kilometres long. To achieve a total distance of 200 kilometres, the route will be completed multiple times throughout the day.